Industrial-quality electric chain hoists with 230 V and 400 V

Electric chain hoists from transprotec are easy and safe to operate. Our electric chain hoists are characterized by their compact, robust and maintenance-friendly design. Each of our electric chain hoists is equipped with gear limit switches and maintenance-free brakes. Electric chain hoists in the P and T-ECH series also have IP 65 and IP 66 protection, making them ideal for outdoor use.

Electric chain hoist model P (IP 66) 125 kg to 37,000 kg

Heavy-duty electric chain hoist model SL 4 t bis 25 t

Electric chain hoist model T-ECH 125 kg to 6,300 kg

Electric chain hoist model ST 125 kg bis 6.300 kg

Electric chain hoist model ST Speed-Line 125 kg to 5,000 kg

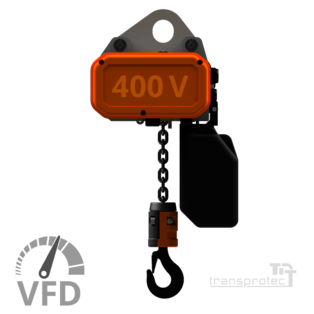

Electric chain hoist model ST-VFD 125 kg bis 2.000 kg

Electric chain hoist with eyelet suspension

The eyelet suspension is the basic version. The electric chain hoist is installed in the trolley using the eyelet. There are also different versions with one or two holes.

Electric chain hoist with trolley

When purchasing electric chain hoists with electric trolleys, you have the advantage that you can also move loads sideways. Electric trolleys are available in different versions, both in terms of the overall height and the speed at which these trolleys can be moved.

Electric chain hoist with hook suspension

For the stationary operation of electric chain hoists, you can choose a hook suspension, which can be easily attached to an attachment point.

Heavy-duty electric chain hoists

Powerful technology for demanding applications. Our solutions not only offer performance and reliability, but also optimize efficiency and safety in your operations.

- Load capacities up to 37 t

- Flexible configuration options

- Durable and robust

Electric chain hoist with push trolley

If you want not only to lift your load with the chain hoist but also to move it sideways, you will need a trolley. A manually operated trolley can, for example, be a push trolley.

Your customized configuration:

Maintenance and care of the load chain / chain lubrication

Every electric chain hoist has a load chain that is subject to enormous stresses. To minimize wear on the load chain and the chain sprocket of the hoist and to prevent damage to the load chain and the chain hoist, it is necessary to check and lubricate the load chain regularly.

Maintenance and care of the load chain / chain lubrication

With a double fall electric chain hoist, there is a risk of the load hook twisting. In addition to the descriptions in the operating instructions, the video presents the problem of twisted load hooks and provides instructions for the correct positioning of the load chain including the load hook.

Electric chain hoists are primarily used on crane systems or rail systems in conveyor technology. They can also be installed in stationary applications. Special applications include the stage and entertainment industry. Various standards can apply here, depending on the requirements profile. These classifications within the BGV standards specify in detail which technical requirements electric chain hoists must fulfill for the respective application.

Employer's liability insurance association regulations specify in detail which technical requirements electric chain hoists must meet for the respective application.

What should you look out for when buying electric chain hoists? This guide can help you to get an initial idea of which chain hoist could be suitable for your application.

1. selecting the load capacity

What load do you want to lift?

It is better to choose the next higher load capacity level, as the automatic overload protection will stop your chain hoist if it is overloaded.

2. classification of the operating mode

How many times per day/hour do you expect to use the appliance?

The ISO (FEM) classification provides information on the maximum number of operations on the control switch per hour. The operating group classification can usually be found in the detailed view. The higher the number after the “M”, the more intensively the electric chain hoist can be used.

| Operations per hour | Duty cycle |

M3 (1Bm) | 150 | 25% ED |

M4 (1Am) | 180 | 30% ED |

M5 (2m) | 240 | 40% ED |

M6 (3m) | 300 | 50% ED |

M7 (4m) | 360 | 60% ED |

3. lifting height

Two factors play a role in determining the correct lifting height for your electric chain hoist:

The suspension height is also decisive for the length of the control cable of the control block if you opt for a wired floor control system.

4. type of control

We distinguish between two basic types of control:

5 The lifting speed

You can choose between three different types of speed control:

- one lifting speed

- two lifting speeds (main hoist and fine hoist) by means of pole-changing.

Electric chain hoists with main and fine lifting speeds are particularly recommended for positioning heavy loads.

Infinitely variable speed

Our standard hoist speeds are 8 m/min, main stroke, with 2 m/min fine stroke. The P model can achieve a main hoist speed of over 20 m/min for loads up to 500 kg. As a rule, the greater the load to be lifted, the slower the lifting speed. The number of chain strands also has an influence on the possible speed. Chain hoists with only one chain strand generally have a more powerful motor than double-strand electric chain hoists with the same load capacity and can therefore lift or lower the load faster.

Electric chain hoist advice

Get in touch with our chain hoist experts and find the right electric chain hoist together.

Phone: +494102 7789-600

E-Mail: info@transprotec.de

A chain hoist is not a crane as such, but a lifting device that can be used in conjunction with a crane or other lifting device. The chain hoist is therefore a component of the crane, but is not a crane in its own right.

For the purposes of this accident prevention regulation DGUV V52, cranes are hoists that can lift loads with a load-bearing device and also move them in one or more directions,

Electric chain hoists can be operated using different types of control. One option is direct control, in which a control current of 400 V or 380 V is used. Another type is contactor control, which works with a lower control current of 24 V or 42 V. Both types of control are widely used in industry and are selected depending on the application and safety requirements.

There are various suspension and movement options for electric chain hoists. Eye suspension and hook suspension are used for stationary attachment. Rolling trolleys, reel trolleys and electric trolleys are available for mobility. Roller trolleys allow manual movement, reel trolleys allow movement by pulling on a chain, and electric trolleys offer motorized movement for maximum efficiency and comfort when moving loads.

Depending on their degree of protection, electric chain hoists can be used indoors or outdoors. For outdoor use, a chain hoist with protection class IP65 should be used. In any case, it is advisable to provide weather protection against precipitation. Chain hoists are designed exclusively for vertical operation.

Chain hoists specially manufactured for the ATEX area are produced in accordance with the classification of potentially explosive atmospheres:

| Flammable substances | Classification of potentially explosive atmospheres | Device group | Device group | Probability |

|---|---|---|---|---|

| Gases & vapors | Zone 0 | Ii | 1G | Constant, long-term, frequent |

| Gases & vapors | Zone 1 | Ii | 2G or 1 G | Occasionally |

| Gases & vapors | Zone 2 | Ii | 3G or 2G or 1G | Probably not |

| Dusts | Zone 20 | Ii | 1D | Constantly |

| Dusts | Zone 21 | Ii | 2D or 1D | Occasionally |

| Dusts | Zone 22 | Ii | 3D or 2D | Probably not |

To define the service life of an electric chain hoist, it is classified into corresponding drive unit groups based on its mode of operation. The classification is based on the use of the device per day within a year (service life class). The frequency of the full load or intensity of the load is taken into account.

| Engine group | 1Bm/M3 | 1Am/M4 | 2m/M5 | 3m/M6 | 4m/M7 |

|---|---|---|---|---|---|

| Theoretical use D (hours=h) | 400 | 800 | 1600 | 3200 | 6300 |

| Operations / hour | 150 | 180 | 240 | 300 | 360 |

| Duty cycle (ED) | 25% | 30% | 40% | 50% | 60% |